OEM China Ecb 10022ab Ansi Z358.1 As 4775 Combination Unit Of Drench Emergency Shower Eyewash With Abs Bowls And Foot Pedal

The corporation keeps to the operation concept “scientific management, superior quality and performance primacy, consumer supreme for OEM China Ecb 10022ab Ansi Z358.1 As 4775 Combination Unit Of Drench Emergency Shower Eyewash With Abs Bowls And Foot Pedal, Since establishment inside the early 1990s, we have now build our sale network in USA, Germany, Asia, and several Middle Eastern countries. We goal to get a top class supplier for around the globe OEM and aftermarket!

The corporation keeps to the operation concept “scientific management, superior quality and performance primacy, consumer supreme for Industrial Shower, Safety Eyewash, Safety Shower, Till now, the merchandise list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you’ll be served with premium quality consultant service by our after-sale group. They will help you get comprehensive acknowledge about our items and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any delighted co-operation.

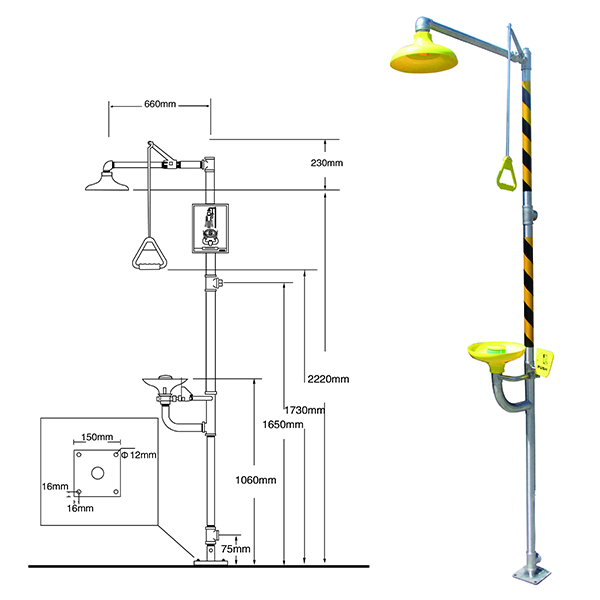

Technical Data:

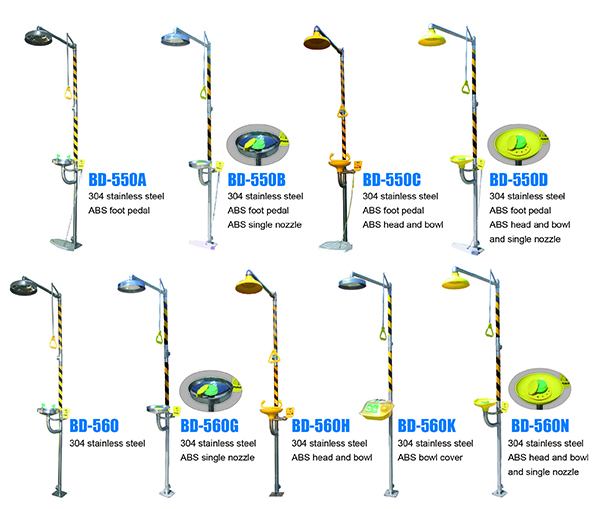

Head: 10” stainless steel or ABS

Eye Wash Nozzle: ABS spraying with 10” ABS waste water recycle bowl

Shower Valve: 1” 304 stainless steel ball valve

Eye Wash Valve: 1/2” 304 stainless steel ball valve

Supply: 1 1/4″ FNPT

Waste: 1 1/4″ FNPT

Eye Wash Flow ≥11.4 L/Min, shower flow≥75.7 L/Min

Hydraulic Pressure: 0.2MPA-0.6MPA

Original Water: Drinking water or filtered water

Using Environment: Places where has hazardous substance splashing, such as chemicals, hazardous liquids, solid, gas and so on.

Special Note: If the acid concentration is too high, recommend to use 316 stainless steel.

When using ambient temperature below 0℃, use antifreeze eye wash.

The eye wash & shower is made of high quality 304 stainless steel.

Can install anti-scalding device to avoid the media temperature is too high in the pipe after the sun exposure and cause user scalding. The standard anti-scalding temperature is 35℃.

Standard: ANSI Z358.1-2014