-

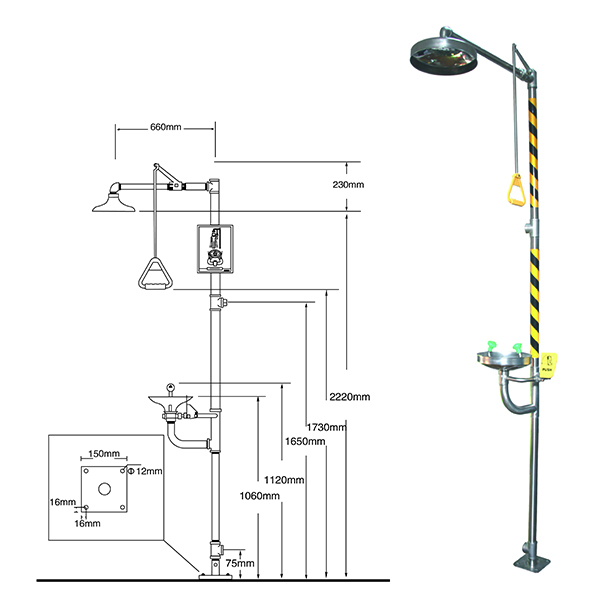

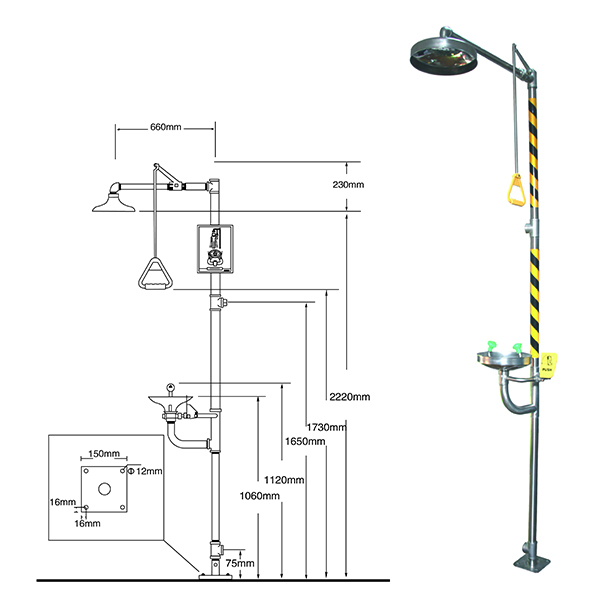

Installation Location In general, the ANSI standard requires that emergency equipment be installed within 10 seconds walking distance from the location of a hazard (approximately 55 feet). The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not re...Read more »

-

Nowadays, eyewash is no longer an unfamiliar term. Its existence greatly reduces potential safety hazards, especially for people working in dangerous places. However, the use of eyewash must be paid attention to. In the manufacturing process of the eye wash, the water pressure test value is very ...Read more »

-

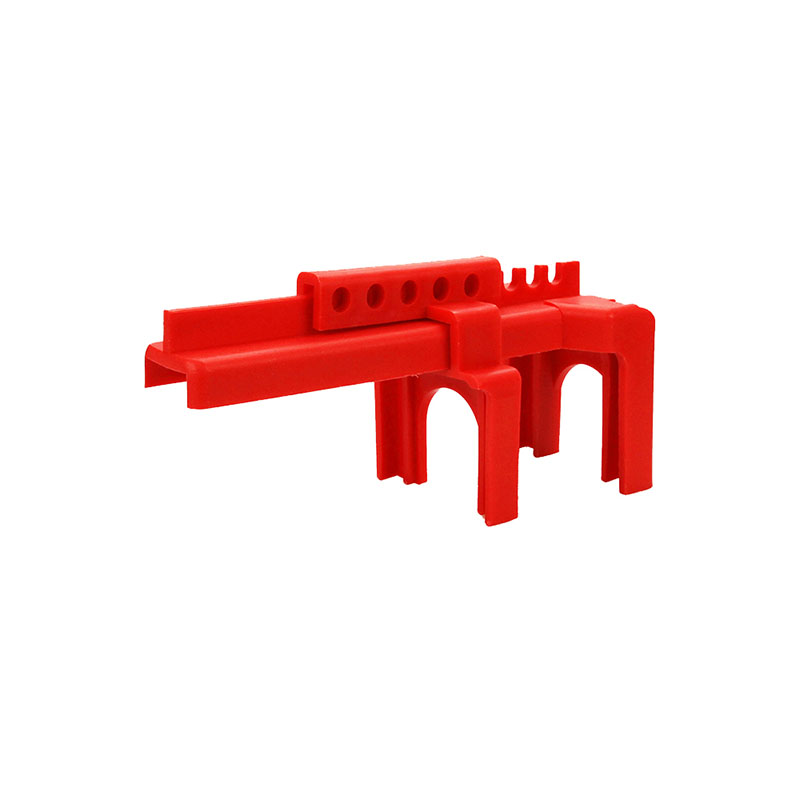

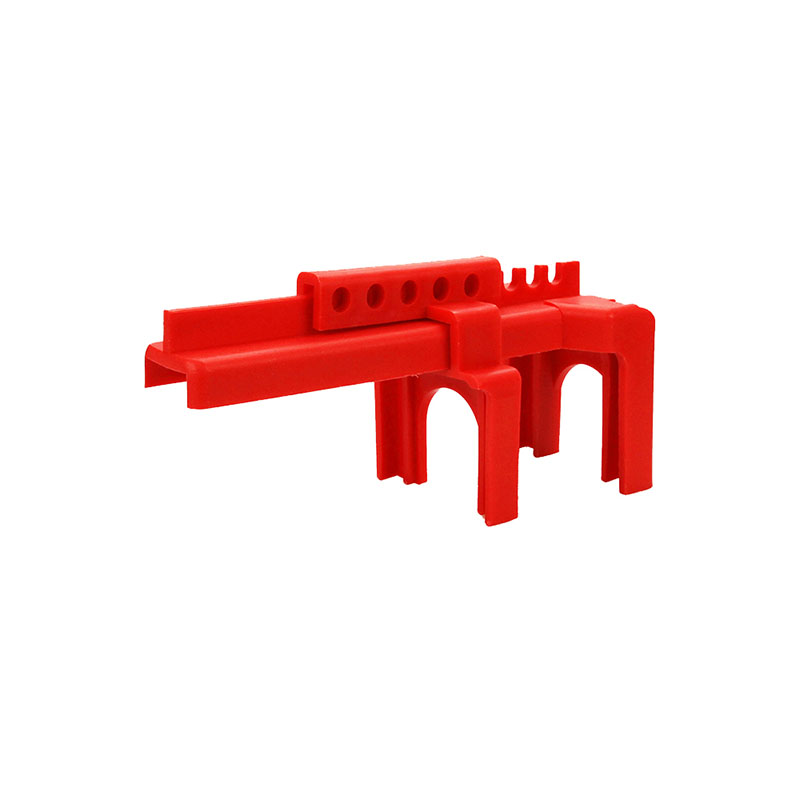

Emergency stop lockouts are an important safety measure in industrial environments to prevent accidents and protect workers from hazardous situations. This safety device is designed to quickly and efficiently shut down machinery or equipment in an emergency, keeping personnel safe and preventing ...Read more »

-

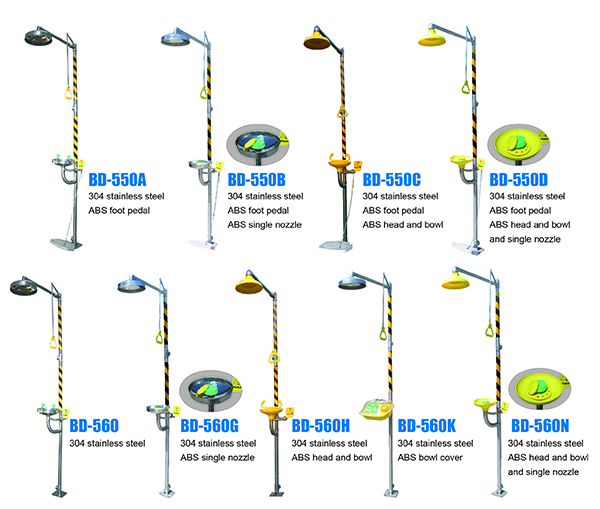

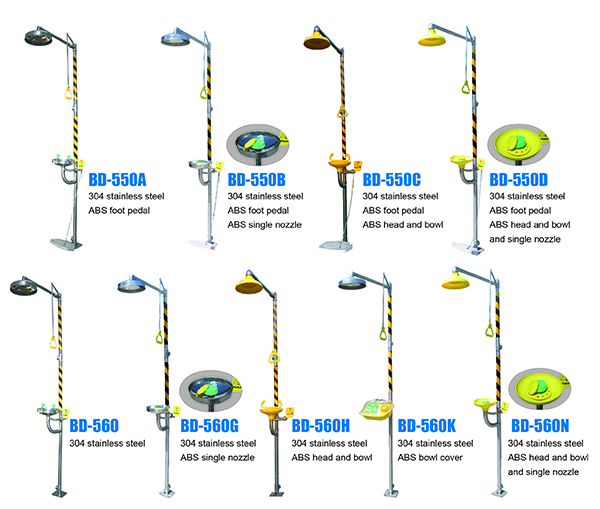

Eyewash stations are an important safety feature in any workplace where employees may be exposed to hazardous materials or substances that could harm their eyes. These stations are designed to flush the eyes immediately in the event of an emergency, helping to minimize the risk of injury and prot...Read more »

-

A hasp lockout is a safety device used to prevent the operation of energy sources such as electrical switches, valves, or circuit breakers during maintenance or servicing. It typically consists of a metal clamp with multiple holes that can be used to secure the device with a lock or tag. This pre...Read more »

-

A lockout tagout (LOTO) station is a centralized location in a workplace where lockout tagout equipment is stored and managed. It typically includes a designated area with hooks or compartments for storing padlocks, lockout hasps, tags, safety lockout devices, and other necessary tools and equipm...Read more »

-

A lockout tagout (LOTO) kit is used in industrial and commercial settings to ensure the safety of workers during equipment maintenance or repair. It typically includes padlocks, lockout hasps, tags, and other devices that are used to physically lock and tag the energy-isolating devices of machine...Read more »

-

9.png)

What is the ideal renewal cycle of locks, and how long is the current domestic user’s general lock renewal time? What security risks will be brought if the replacement is not in time? Due to the uneven quality of hardware products, the product life cycle is very different. However, accordi...Read more »

-

The importance of safety lockout cannot be overstated in any workplace. Safety lockout, also known as a lockout/tagout system, is a critical safety procedure that ensures hazardous machinery and equipment is shut down properly and cannot be started up again until maintenance or repairs are comple...Read more »

-

Valve lockout is an important safety measure in industrial environments to prevent valves from accidentally releasing hazardous substances or energy. It involves the use of a locking device to secure the valve in the closed or open position, ensuring that the valve is inoperable until the locking...Read more »

-

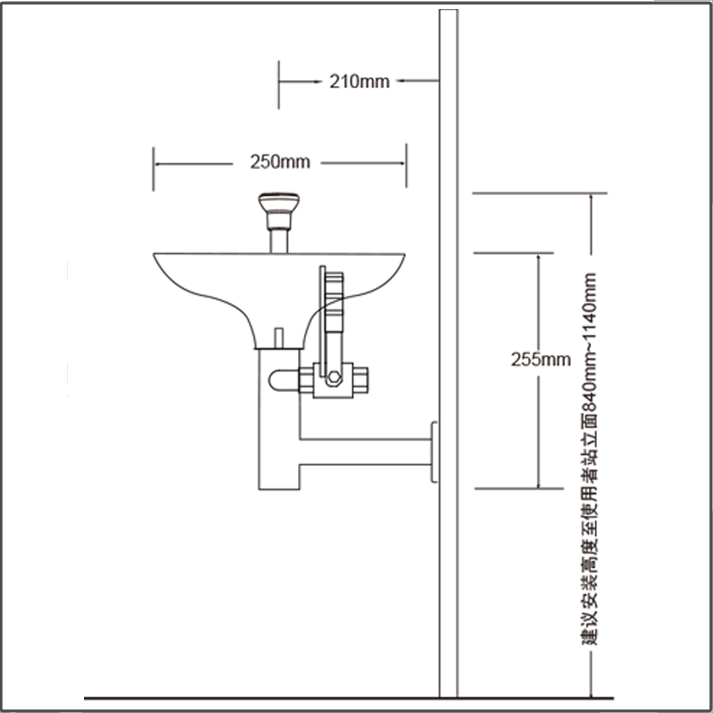

Proper use of eyewash stations and emergency showers is critical to avoiding secondary injuries when exposed to hazardous materials or substances. Here are the steps to use an eyewash to avoid secondary injury: 1. Determine the location: Know where the nearest eyewash stations and emergency showe...Read more »

-

Lockout/tagout procedures are used to protect workers from unexpected activation of machinery or equipment during maintenance or repairs. Here are the steps to use lockout/tagout to keep your workplace safe: 1. Identify energy sources: Before starting any maintenance or repair work, identify all ...Read more »

-

Gate valve lockout devices are designed to prevent the operation of gate valves in industrial settings. These devices are crucial for ensuring the safety of workers and preventing accidental or unauthorized valve operation during maintenance, repair, or servicing activities. Gate valve lockout de...Read more »

-

Ball valve lockout devices are used to prevent the accidental or unauthorized operation of ball valves in industrial settings. These devices are designed to fit over the valve handle, preventing it from being turned and effectively locking the valve in place. There are various types of ball valve...Read more »

-

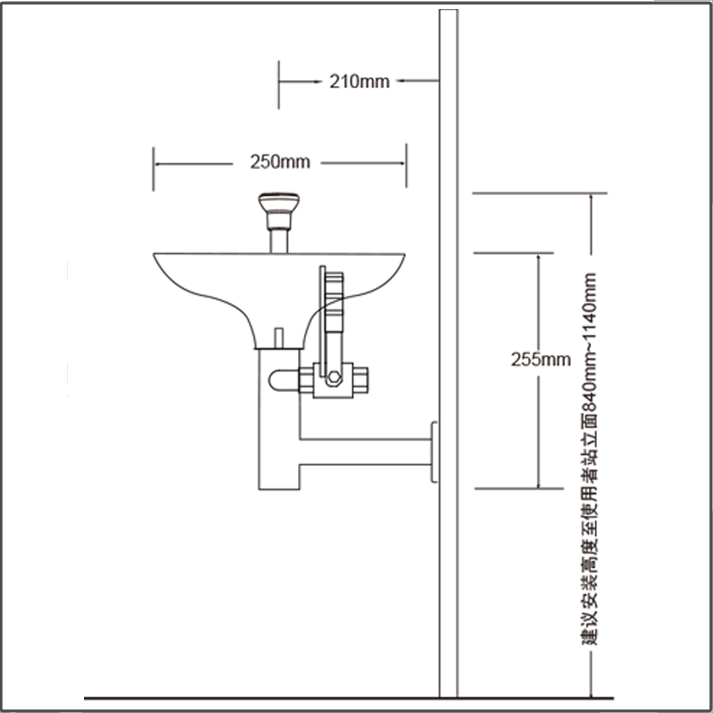

Emergency eyewash and shower units are designed to rinse contaminants from the user’s eyes, face or body. As such, these units are forms of first aid equipment to be used in the event of an accident. However, they are not a substitute for primary protective devices (including eye and fac...Read more »

-

As a necessary eyewash device during factory inspection, it is more and more widely used. However, many people do not know the working principle of eyewash device very well. Today I will explain it to you. As the name suggests, the eyewash is to flush out harmful substances. When the staff is in...Read more »

-

When it comes to workplace safety, nothing is more important than having the proper equipment to respond to potential emergencies. One of the most important pieces of safety equipment that every workplace should have is a standing eyewash station. If your eyes are injured or exposed to harmful ch...Read more »

-

Rapid response portable purifying shower: ensuring safety in emergencies If a workplace incident or chemical exposure occurs, prompt and effective decontamination of affected individuals is critical to minimizing the risk of injury or long-term health effects. This is where rapid response portabl...Read more »

-

Lockout/tagout requirements are an important part of workplace safety. These procedures are designed to protect workers from hazardous energy sources such as electricity, steam, natural gas and water. By implementing safe lockout/tagout measures, employers can prevent workplace accidents and keep...Read more »

-

Cable lockouts are an important safety measure in many workplaces. It is a key element of lockout/tagout (LOTO) procedures designed to prevent accidents and injuries caused by the accidental release of energy during maintenance and repair activities on machinery and equipment. In this article, we...Read more »

-

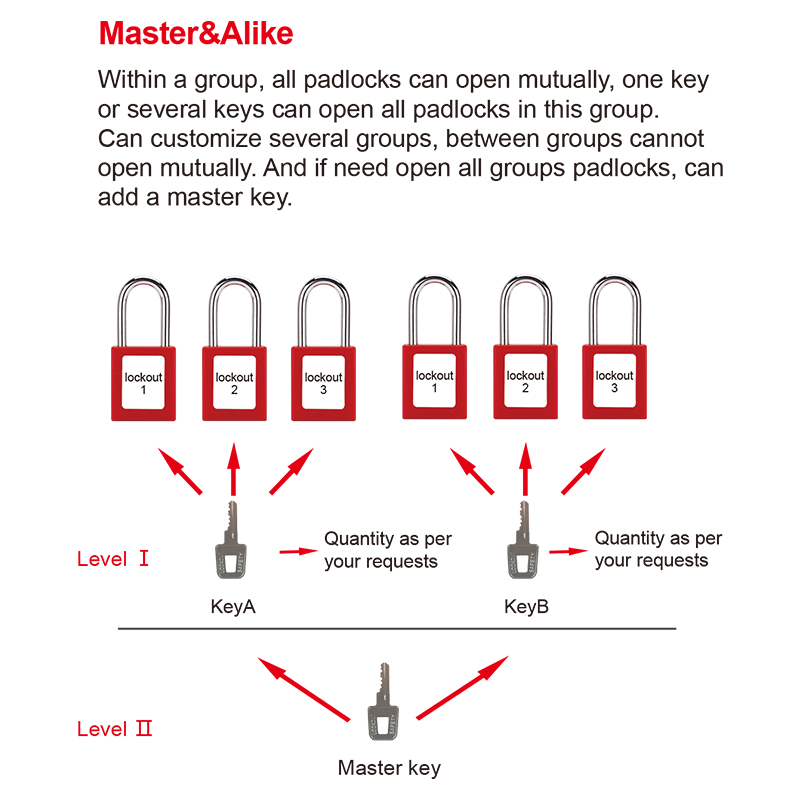

A safety lockout padlock is a specially designed lock used as part of lockout tagout (LOTO) procedures to prevent the accidental or unauthorized energization of machinery and equipment during maintenance or servicing. These padlocks are typically brightly colored and uniquely keyed to ensure that...Read more »

-

Lockout tagout (LOTO) refers to the safety procedure designed to prevent unexpected start-up of machinery or equipment during maintenance or service. It involves the use of locks and tags to isolate the energy sources of the equipment, ensuring that it cannot be energized until the maintenance wo...Read more »

-

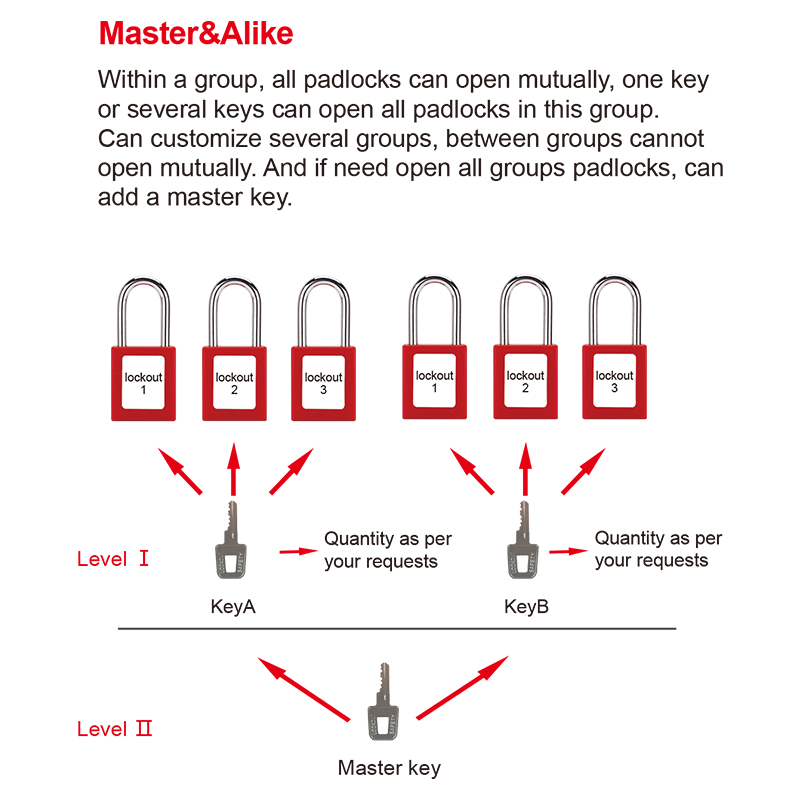

Key Management System– we can know it from its name. The purpose of it is avoiding the mix of the key. There are four types keys to satisfy the customers’ request. Keyed to Differ:Each padlock has unique key, padlock cannot open mutually. Keyed Alike: Within a group, all padlocks can...Read more »

-

Lockout/tagout is an important safety procedure in many industries and is designed to protect workers from hazardous energy sources. It involves the use of safety locks and tags to prevent accidental activation or release of stored energy during equipment maintenance or repair. The importance of ...Read more »

-

E-mail

-

WhatsApp

-

Facebook

9.png)