The fully automatic polyurethane shoe production system developed by Marst is a breakthrough in traditional technology, which can greatly improve production efficiency, improve product quality stability and reliability, and reduce labor costs and improve product quality for labor-intensive shoe companies, realize modern shoe production.

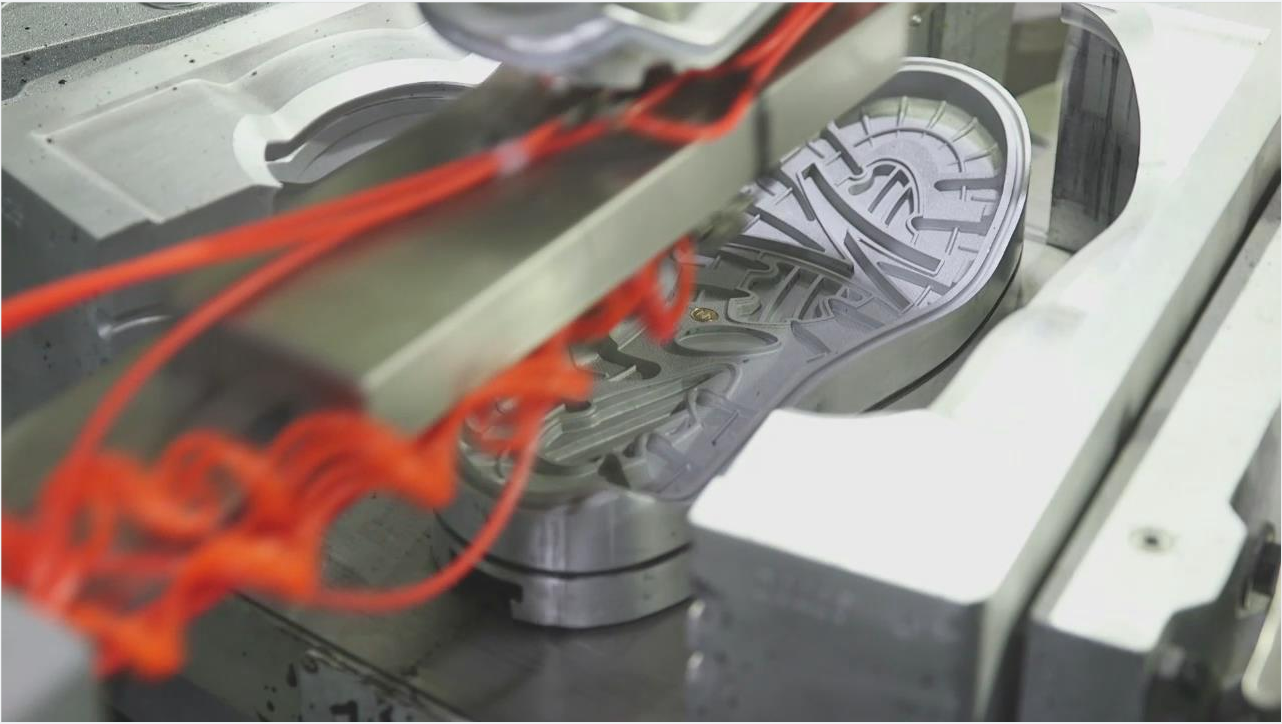

1. Automatic roughing system

The intelligent automatic roughing system eliminates many shortcomings of artificial roughing and the expensive price of robot roughing. The double heads design is adopted, which can quickly select the template according to the recognition of the shoe size and quickly rough. After the processing is completed, the turntable can be quickly rotated and switched to the next station with high-speed and accurate positioning!

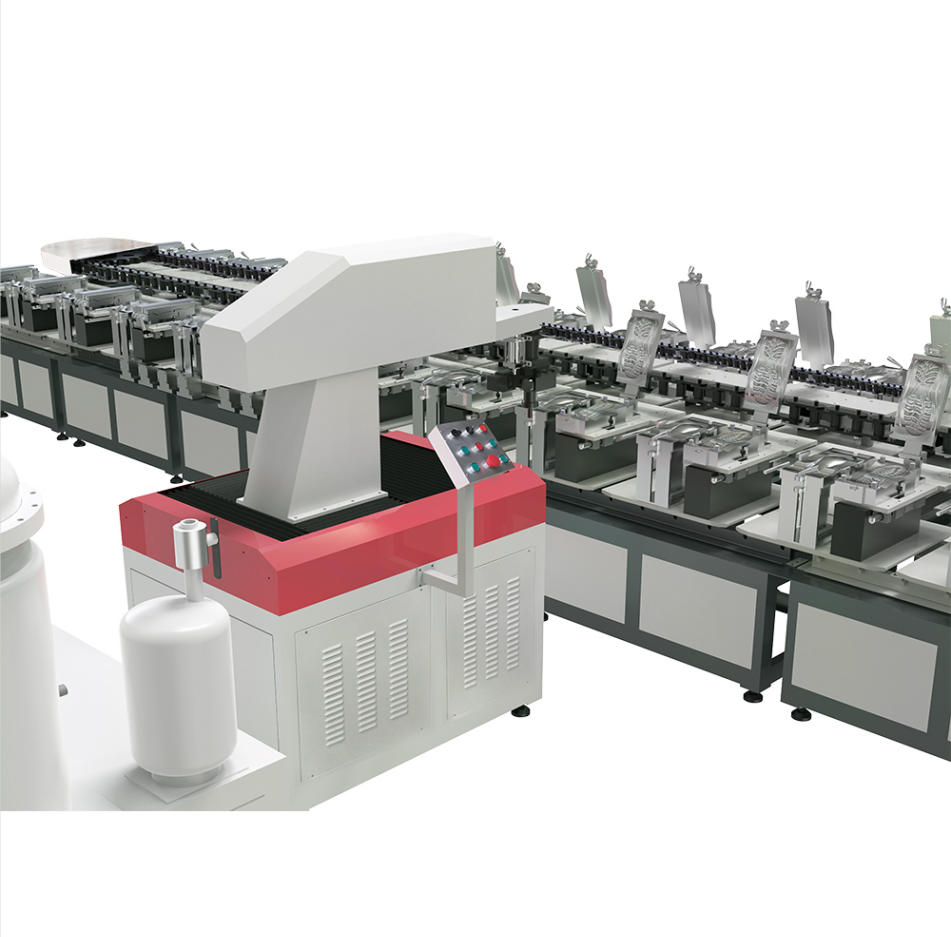

2. Automatic molding assembly line

Polyurethane continuous shoe sole molding line, integrated with modern Internet + technology, can realize automatic injection, automatic mold opening and closing, automatic injection of mold release agent, automatic control of mold temperature, and automatic lifting of bottom mold.

3. High efficiency flow production process with two-line integration

The front-stage shaping roughing disc machine and the rear-stage injection molding machine are integrated together from the finished shoe last, upper cover last, last spray glue, steel toe cap, corner brush glue, baking glue, stretch front upper, heel pressing, and roughing, double-density injection molding to the last failure, the entire production process only needs 4 to 5 people. Eliminates the cumbersomeness of the secondary last of the traditional process, and effectively integrates humans and machines to form efficient production! Greatly improve production efficiency, reduce labor costs so as to make a qualitative leap in product quality, and fundamentally eliminate the dependence on personnel and technology in production!

In the future, we will continue to research and develop on equipment intelligence, precision, and efficiency, and work hard for future shoe companies to achieve the goal of unmanned factories.

Post time: Dec-10-2021